When to Outsource Your Pharmaceutical Packaging Operations?

Pharmaceutical packaging plays a crucial role, beyond just protecting a product. For both over-the-counter (OTC) and prescription (Rx) manufacturers, packaging must balance safety, compliance, and patient ease-of-use. Partnering with a contract packaging organization (CPO) can help companies manage supply chain challenges and expand their market reach more effectively.

Navigating Supply Chain Complexity with Pharmaceutical Packaging

Outsourcing packaging can be a turning point for pharmaceutical companies. When in-house teams are already at capacity, it’s hard to grow or take on new projects. By partnering with a contract packaging organization, companies can scale more easily—without needing to invest in new equipment, facilities, or pull resources away from what they do best. It’s a flexible way to support growth and bring new products to market faster.

Building Resilience in Your Supply Chain

Pharmaceutical supply chains are complex, with every stage—from sourcing raw materials to delivering finished products—playing a critical role. Manufacturers face constant challenges: fluctuating demand, strict regulations, and the risk of supply chain disruptions. Partnering with a pharmaceutical contract packaging organization (CPO) can help companies navigate these challenges by adding stability, flexibility, and the ability to respond quickly to change.

Tapping Into Specialized Expertise

Packaging for solid oral dose products—like tablets, capsules, and soft gels—requires deep expertise. Effective packaging needs to support patient adherence, meet regulatory requirements, and stand out in the market. By outsourcing to experienced partners offering advanced services such as blister packaging and high-speed bottling, pharmaceutical companies gain access to proven processes, technology, and quality control systems designed specifically for regulated healthcare environments.

The Strategic Advantages of Outsourcing

Agility in a Changing Market

The pharmaceutical industry moves fast. Outsourcing packaging allows companies to respond quickly to product changes, regulatory updates, or new market demands. Specialized partners help ensure compliance—such as with serialization and track-and-trace requirements—while enabling faster market entry and improved supply chain responsiveness.

Focus on Core Capabilities

Delegating packaging operations frees internal teams to focus on what matters most: research, development, and bringing new therapies to market. Outsourcing lets you prioritize innovation without sacrificing execution.

Cost Efficiency

Outsourcing helps companies avoid large capital investments in packaging infrastructure and technology. It transforms fixed costs into variable ones, aligning expenses more closely with production needs and making it easier to scale up or down.

A Strategic Partnership, Not Just a Service

Outsourcing pharmaceutical packaging is more than a handoff—it’s a strategic decision. The right partner doesn’t just execute; they help you improve performance, ensure compliance, and support growth in a competitive industry. Whether you’re looking to scale, improve efficiency, or access specialized technologies, outsourcing can help you meet your business goals.

Work with a certified, experienced packaging partner equipped with advanced technology—like high-speed bottling and multi-format blistering—designed for the needs of regulated pharmaceutical products.

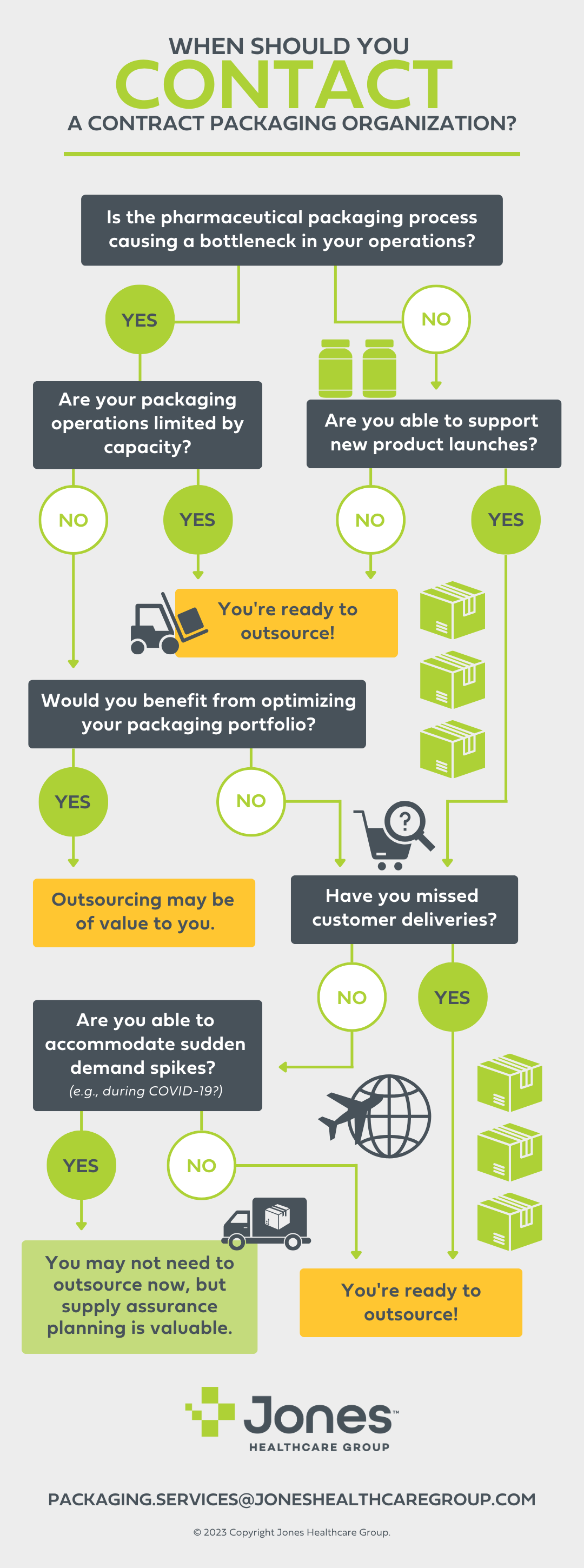

Use our quick decision flowchart to see if outsourcing is right for your business: